Rules of operation of wheels and rollers

Failure to comply with the lower rules on wheels and rollers relieves the manufacturer and seller of any liability and warranty.

1. Product information and intended operating conditions.

Wheels and rollers are interchangeable technical elements attached to equipment, furniture, appliances, etc. to ensure their mobility.

This information applies to wheels and rollers, in particular to passive control rollers (rotary rollers), intended only for use on non-motorized vehicles and equipment (hereinafter referred to simply as objects), which are not, as a rule, in constant motion and moving at speed up to 4 km / h.

Within the framework of this information, the following classification of wheels and rollers by field of application is possible:

Furniture and housing, for example:

- upholstered furniture, cabinets;

Service sector:

- the usual sphere of services, for example, shopping carts, office furniture; medical services, for example: hospital beds;

Field of industrial production, for example:

- transport equipment with medium and heavy lifting capacity.

The foreseen operating conditions include, first of all, the technically correct installation:

a) The product must be firmly connected to the object in all places provided for this.

b) The object must have sufficient strength in the indicated places.

c) During the installation process, no violation or change of the originally provided product functions is allowed.

d) The rotary rollers must be mounted so that their rotary axis is in a vertical position.

e) Fixed rollers must be mounted so that the axles of their wheels lie on parallel straight lines.

f) The swivel casters installed at the facility must be of the same type.

When installing fixed rollers in addition to the rotary rollers, only the use of rollers recommended by the manufacturer is allowed.

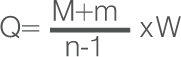

g) The load on one wheel is calculated by the formula:

Where:

Q - load on one wheel,

M is the weight of the transported cargo,

m is the weight of the trolley,

n is the number of wheels

W - safety factor,> 1 under non-standard operating conditions.

For operation in places with high humidity, in the open air or near the sea, as well as surrounded by aggressive and corrosive substances, it is necessary to use rollers special for these operating conditions.

For operation in the temperature range below + 5 ° C and above + 30 ° C, it is necessary to use rollers special for these operating conditions. In no case is it permitted to operate in these conditions standard rollers with a load corresponding to their rated load capacity.

The wheel, bracket, brake and locking systems, as well as the wheel axle, are a single functional unit. The manufacturer and seller are only responsible for genuine products.

A prerequisite for the correct selection of rollers is the availability of data on all possible loads. Otherwise, calculations should be made with a large margin of safety.

2. Violation of operating conditions. Violations of operating conditions or unforeseen operating conditions include:

a) Operation of wheels and rollers with loads exceeding the permissible load capacity specified in the catalog.

b) Use of wheels and rollers on an unsuitable, uneven surface; the height of obstacles should not exceed 5% of the diameter of the wheel.

c) Use in conditions of high or low temperatures of wheels not intended for this purpose.

d) Movement with the force of objects with brake-activated rollers.

e) Wheels and rollers are exposed to particularly aggressive substances and compounds.

e) The impact of rough dynamic loads, as well as the fall of wheels and rollers.

g) Violation of the integrity of the bandage by foreign bodies.

h) Exceeding the permissible (4 km / h) speed of the wheels and rollers.

i) Transportation of products standing on wheels inside the body of a truck or other vehicle, without prior approval.

j) Changes of any kind inconsistent with the manufacturer.

3. Technical data

Requirements for wheels and rollers based on technical data not specified in our catalogs, brochures, etc., must be agreed with us.

4. Maintenance

Wheels and rollers should be regularly subjected to the following preventive maintenance as necessary:

- bearing lubrication,

- control and tightening of detachable connections.

For cleaning, use only products that do not contain any damaging or corrosive elements.

Rollers, as well as their individual functional units, are subject to immediate replacement if they fail.

5. Conclusion

By purchasing wheels and casters, you agree to all the conditions specified in this manual.