Selection Criteria and Scope of Application of Wheels for Waste Containers of Solid Waste

Technical features

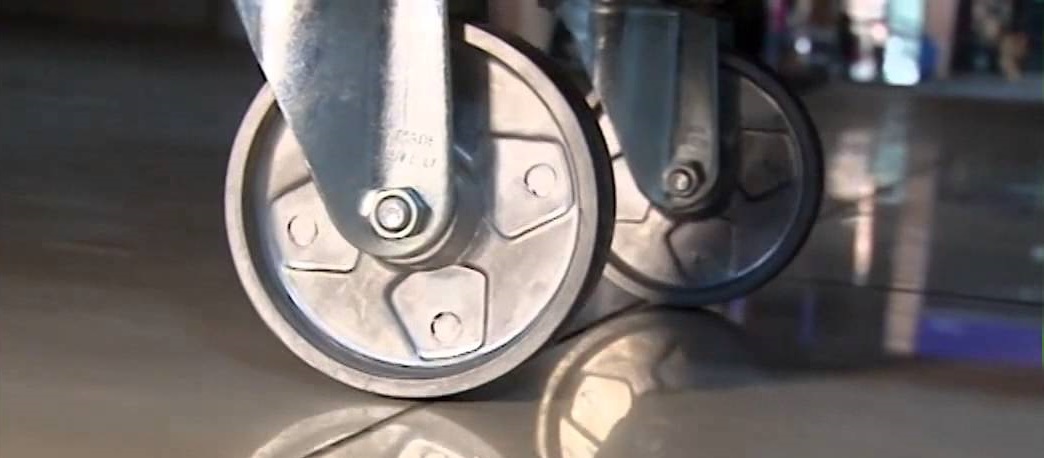

Wheels for garbage cans of solid household waste are produced on modern equipment using innovative technologies and wear-resistant raw materials. The products are based on standard black rubber / polypropylene. The material of the rolling surface demonstrates good slip resistance, does not leave marks when moving the MSW container. Polypropylene is resistant to the negative effects of aggressive substances, high humidity, temperature extremes (it does not crack in the cold, does not deform in the summer heat).

In the production of rims, hardened steel of increased hardness is used. The wheel is complemented by a roller bearing, which increases the maneuverability of the equipment being equipped. Products are manufactured with a fastening element (a bracket made of high-quality steel, which increases the reliability of the structure) and without it.

Main technical characteristics of wheels for trash cans:

sizes. When choosing, the outer diameter and the total height of the wheel are taken into account;

product hardness. This figure is 80–85 Shore A;

own weight of the product;

carrying capacity. Depending on design features and diameter, wheels can withstand static loads from 100 to 575 kg;

the presence of a brake mechanism. This design feature improves the performance of the wheel supports for garbage cans;

Operating temperature range. Wheel bearings maintain their performance at t -20– + 60 degrees Celsius.

As a rule, the products are designed for operation at low speeds - up to 4 km / h.

Scope of application

Wheels are used not only to equip garbage containers with solid waste. Products are also used to complete:

rotary ovens (used in confectionery and bakery);

scaffolding;

hearth ovens (the equipment differs in the presence of tiers, is used for baking bakery products) and other mobile equipment.

Another area of using wheels is furniture production.

Products are characterized by increased resistance to static loads, mechanical wear, have a long service life, therefore, they are suitable for use on an asphalt surface, as well as in conditions of poor quality surfaces.

Maintenance

To increase the operational life of the wheels, it is necessary to carry out preventive maintenance in a timely manner. It is forbidden to clean products using agents based on aggressive substances. As necessary, lubricate the bearings and check the condition of the detachable connections.

Reliable supplier

Fregat is a manufacturer of wheels for mobile equipment. The technical characteristics of the manufactured products comply with the requirements of the current quality standards, which is confirmed by the presence of a certificate. The company sells catalog wheel models, and is also ready to fulfill any specific order.